PART 2 - Analysis of Operational Data (Scada)

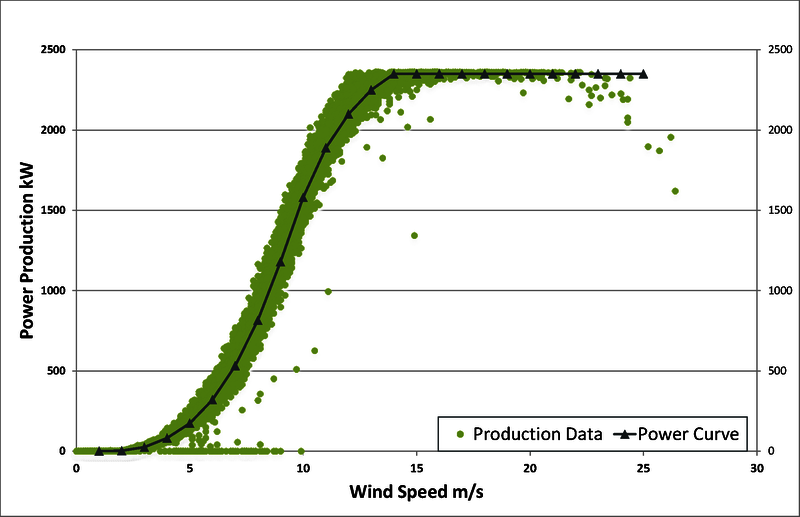

The Analysis of Operational SCADA Data is done by the analysis of 10min SCADA raw data (energy production / status codes / corrected nacelle wind speed / operational modes), which shows the historic real performance of the turbine with its availability, degradation and maintenance procedures.

Correlation with neighboring turbines and their operational data will lead to the identification of suboptimal operation.

Inidcate possible turbine maintenance and operational problems to maximize the efficient use of wind and energetic availability.

Examples:

- Incorrect Sector Management

- Pitch controll malfunctions

- Blade damages

- Yaw system faults

- Too late/ too early cut in/out

Energy Based Availabilty:

Energy Based Availability Analysis considers the quantity of energy not generated due to turbine non-availbility or low performance.

Most of the time the manufacturer is responsible for the maintenance and operation of the wind farm. Usually a time based availability is agreed with the manufacturer and the wind farm owner, where the conditions of the turbine performance during downtime are not considered into contract clauses.

Taking into account that the turbines are likely to suffer downtime under heavy duty, the loss percentage of energy production is likely to be higher than time based downtime percentage.

GEO-NET applies sophisticated methods as outlined in IEC 61400-26-2 to analyze production based availability.

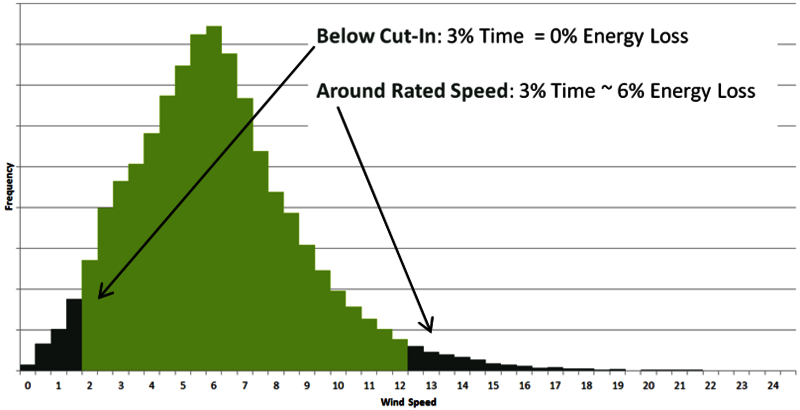

Best-Case: the downtime occur when the turbine is not running at all, which means that the lost production is zero.

Worst-Case: the downtime occur during high wind speeds when the turbine would produce with rated power.

Click here to find out what we can do with this performance information and look into the future with the PART 3 - Long-term correction.